Description

|

MAESTRO: The MMT

Advanced Echelle

Spectrograph

Description |

MAESTRO is a cross-dispersed echelle spectrograph for the MMT, funded

by the National Science Foundation and Steward Observatory, with

support from the MMTO. It is optimized for multi-order, simultaneous

wavelength coverage, with R(theta) = 28,000, or 7.5 km/s when used with

a 0.7 arcsec slit. The best possible spectral resolution, using a 0.3

arcsec slit, is Nyquist sampled with spectral resolution of R=93,000 or

3.2 km/s. The single exposure wavelength coverage is 3150 to 9850

Angstroms with small gaps redward of about 8000 A. Thus MAESTRO is

complementary to the existing multi-fiber Hectochelle

spectrograph

at the MMT. It is optimized for high throughput in the UV, so is the

instrument of choice for faint, rare objects such as quasars and

metal-poor stars, where wavelength coverage is important.

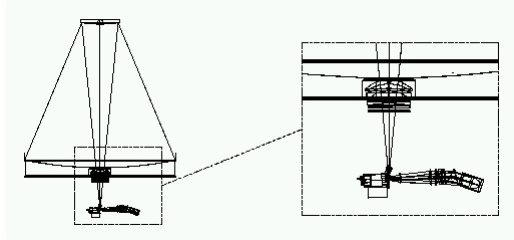

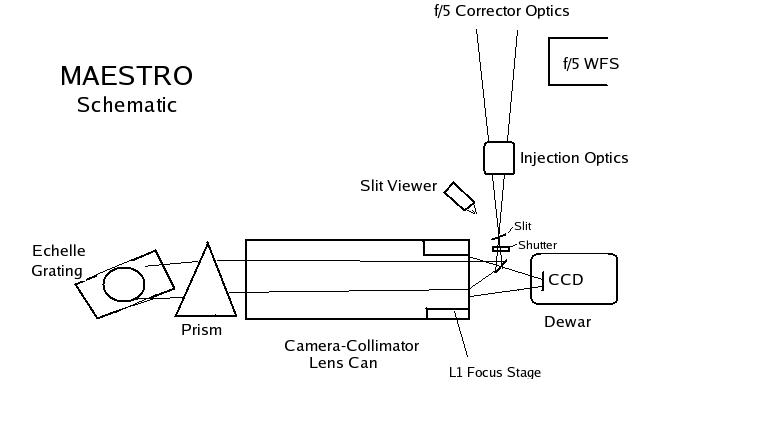

MAESTRO is located at the f/5 Cassegrain focus, attached to the instrument rotator. It uses the f/5 secondary, spectroscopic corrector optics, and atmospheric dispersion prism built by Dan Fabricant's group at SAO. The light from the telescope enters the spectrograph through a small doublet (we call the injection optics) which transforms the f/5 beam to f/3. It then passes through the slit, and is turned 90 degrees by a small folding flat mirror. The collimator consists of a set of 6 lenses, and is used in double pass. The overall design is patterned after the MIKE echelle at the Magellan telescope.

The light passes through 3 singlets (BSM51Y, fused silica, PBM18Y) and then a glued triplet of BSM51Y -CaFl-BSM51Y. BSM51Y and PBM18Y are i-Line glasses made by Ohara, which have high ultraviolet transmission. The light then passes through the fused silica prism, the echelle grating, then back through the triplet and 3 singlets, and through a field flattener which is the dewar window, made of fused silica. The CCD is tilted slightly. The first of the 6 lenses (L1) is movable, for focus control. The collimated beam passes through a prism cross-disperser, and then is reflected off a custom ruled echelle grating.

|

|

|

Figure 1: Schematic of MAESTRO, optics and dewar, showing

6.5m Primary mirror, f/5 secondary mirror, corrector optics,

atmospheric dispersion corrector, and spectrograph.

|

The light then passes again through the cross-disperser prism, the lens can, and onto the CCD detector. The dewar window acts as a field flattener. The CCD is tilted slightly to improve optical performance. A schematic of the optical lay-out is shown below.

MAESTRO's beam diameter is 200 mm, set by the maxiumum CaFl blank that was available. The cross-disperser is a 40 degree prism made of fused silica.

The camera-collimator lenses, dewar window and cross-disperser prism were made by Bradley J. Piccirillo, of Optical Solutions, Incorporated, in Charlestown, New Hampshire. The small injection optics were manufactured and mounted by Joe Apples at TORC, in Tucson, Arizona.

The camera-collimator contains a triplet with a large CaFl element in the center. Cargille 1160 oil is used to optically couple the three elements of the triplet. Oil was chosen over an optical glue such as Sylgard in order to allow flexibility later on, should the triplet need to be dismantled for some reason. Cargille 1160 was found to be UV transmissive, and unreactive to Sylgard and the rubber O-ring which seals the oil layers in the lens cells. At the top of the cells, a small pliable tube allows overflow relief. Tests on a small triplet showed a voltaic reaction when plumbing hardware made of brass was used, which discolored the oil severely after a few months. We therefore fabricated pressure relief hardware out of aluminum and used teflon tape to isolate any non-aluminum hardware from contact with the oil.

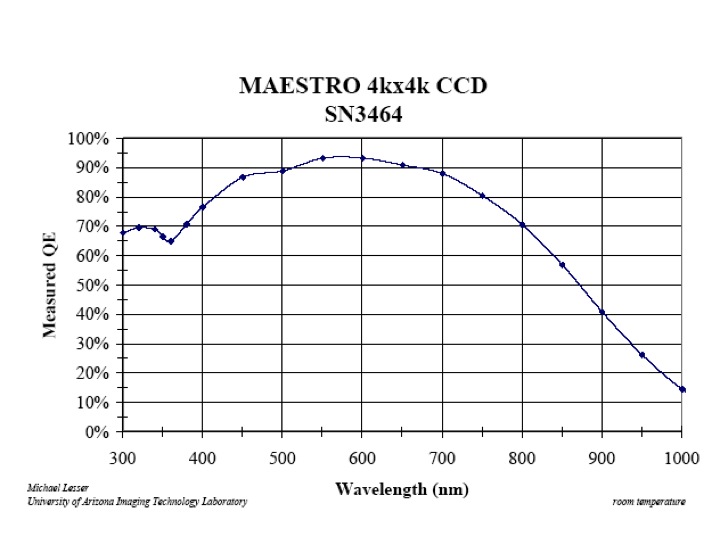

By choosing a prism over a grating cross-disperser, we increase throughput and single exposure wavelength coverage. The cost is that order separation is small in the red. We however optimized the optical design of MAESTRO for the blue, because of the excellent blue sensitivity of the CCDs produced by ITL, and the compelling science enabled by spectroscopy in the near-UV.

The detector is a 4kx4k back-illuminated CCD which was thinned and

AR coated to optimize UV sensitivity, by Mike Lesser's group at the University of Arizona Imaging

Technology Lab (ITL). It

is type JPL4096, UA ITL serial number SN3464. The camera uses an ARC Gen-3 controller, run by an

on-board PC and the AZCAM data

acquisition

software. The user controls the CCD via an IRAF/ICE

interface running on a linux box in the control room. The CCD has

15 micron pixels;

one arcsecond at the slit maps to 6.5 pixels on the detector. The

readnoise in the lab is 3.4 electrons RMS. The quantum efficiency

as measured in the lab is shown below.

The honeycomb sandwich panels were donated by the Hexcel Composites of Casa Grande, Arizona. The individual components were glued together with JB weld with invar reinforcements at most joints. The panel edges were sealed with carbon fiber tape which was glued on with JB weld. Bolt holes were made by gluing pre-made plastic inserts.